Description

This document describes the procedure for manually operating electro pneumatic points.

Not what you are looking for? See more Procedures

Introduction

Some electro pneumatic points can be operated manually at the trackside by a Qualified Worker, others can only be manually operated by a Signals Maintenance Representative.

Electro pneumatic points that can be operated manually at the trackside by a Qualified Worker are operated by push buttons located on the Emergency Operation Lock (EOL) control box.

The push buttons are enabled by either:

- a switch located in the EOL control box, or

- a key that is obtained from an EOL cabinet located near the points.

Electro pneumatic points machines must not be operated manually without the Signallers authority.

Key‑operated points

Switching to trackside control

Qualified Worker

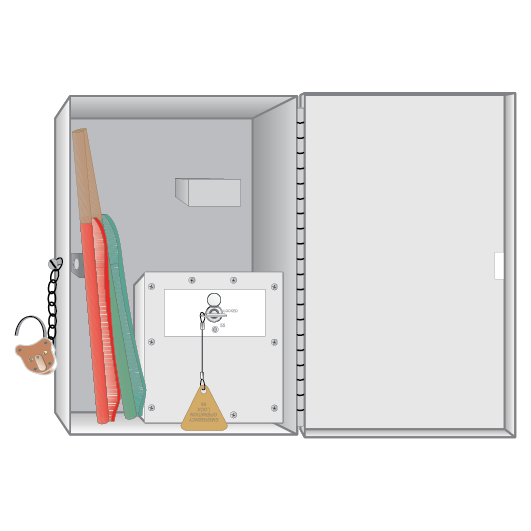

- Find the correct EOL cabinet for the points and unlock it with an SL key.

- If there are instructions in the cabinet to help you to operate the points, read and follow them.

- Turn the EOL key from LOCKED to UNLOCKED. Take it from the cabinet. Removing the key:

- switches the points machines to trackside control, and

- sets the protecting signals at STOP.

- Check the key label to make sure it is the correct key.

Manually operating the points

Qualified Worker

- Check the labels of the points it is necessary to operate.

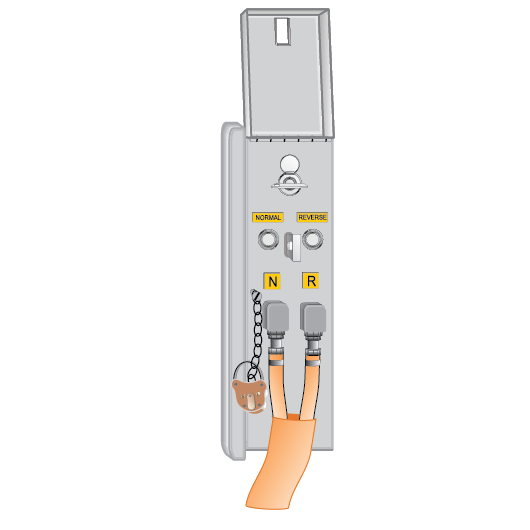

- Locate the corresponding labelled control box for the points. Unlock it with an SL key.

- Insert the EOL key, and give the key a quarter turn in the rotary switch.

There is a 60 second delay before the NORMAL and REVERSE buttons in the control box can be used.

- Push and hold the REVERSE or the NORMAL button, for at least 3 seconds to move the points to the intended position.

If there are several electro pneumatic points machines at a crossover, air pressure in the system operates all points machines together.

- Check points have operated to the intended position.

- Get instructions from the Signaller.

- If necessary, clip and lock the points.

Returning to signal box control

Qualified Worker

- Remove the EOL key from the rotary switch.

- Lock the control box.

- Return the EOL key to the cabinet.

- Turn the EOL key to the LOCKED position and lock the cabinet.

- Ask the Signaller to test the points.

- Confirm with the Signaller that the points operate correctly.

- If the points do not operate correctly, get instructions from the Signaller.

Switch‑operated points

Manually operating the points

Qualified Worker

- Check the labels of the points it is necessary to operate.

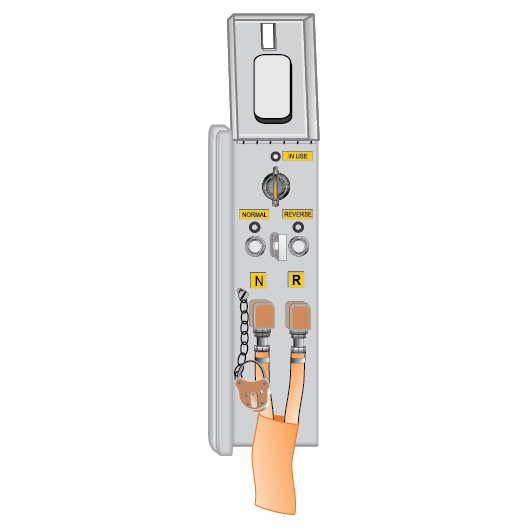

- Locate the corresponding labelled control box for the points. Unlock it with an SL key.

If there are several electro pneumatic points machines at a crossover, air pressure in the system operates all points machines together.

- Turn the IN USE switch a quarter turn clockwise and wait for the white indicator light above the switch to illuminate.

There is a 60 second delay before the NORMALand REVERSE buttons in the control box can be used.

- Push and hold the REVERSE or the NORMAL button, for at least 3 seconds, to move the points to the intended position.

- Check points have operated to the intended position.

- Get instructions from the Signaller.

- If necessary, clip and lock the points.

The N and R lights in the control box do not guarantee the points have operated to the intended position. Points must be checked to ensure they have operated to the intended position.

Returning to signal box control

Qualified Worker

- Give the IN USE switch key a quarter turn anti‑clockwise.

- Check that the white indicator light goes out.

- Lock the control box.

- Ask the Signaller to test the points.

- Confirm with the Signaller that the points operate correctly.

- If the points do not operate correctly, get instructions from the Signaller.