Description

This document describes the procedure for protecting activities associated with in-service rail traffic.

Not what you are looking for? See more Procedures

Introduction

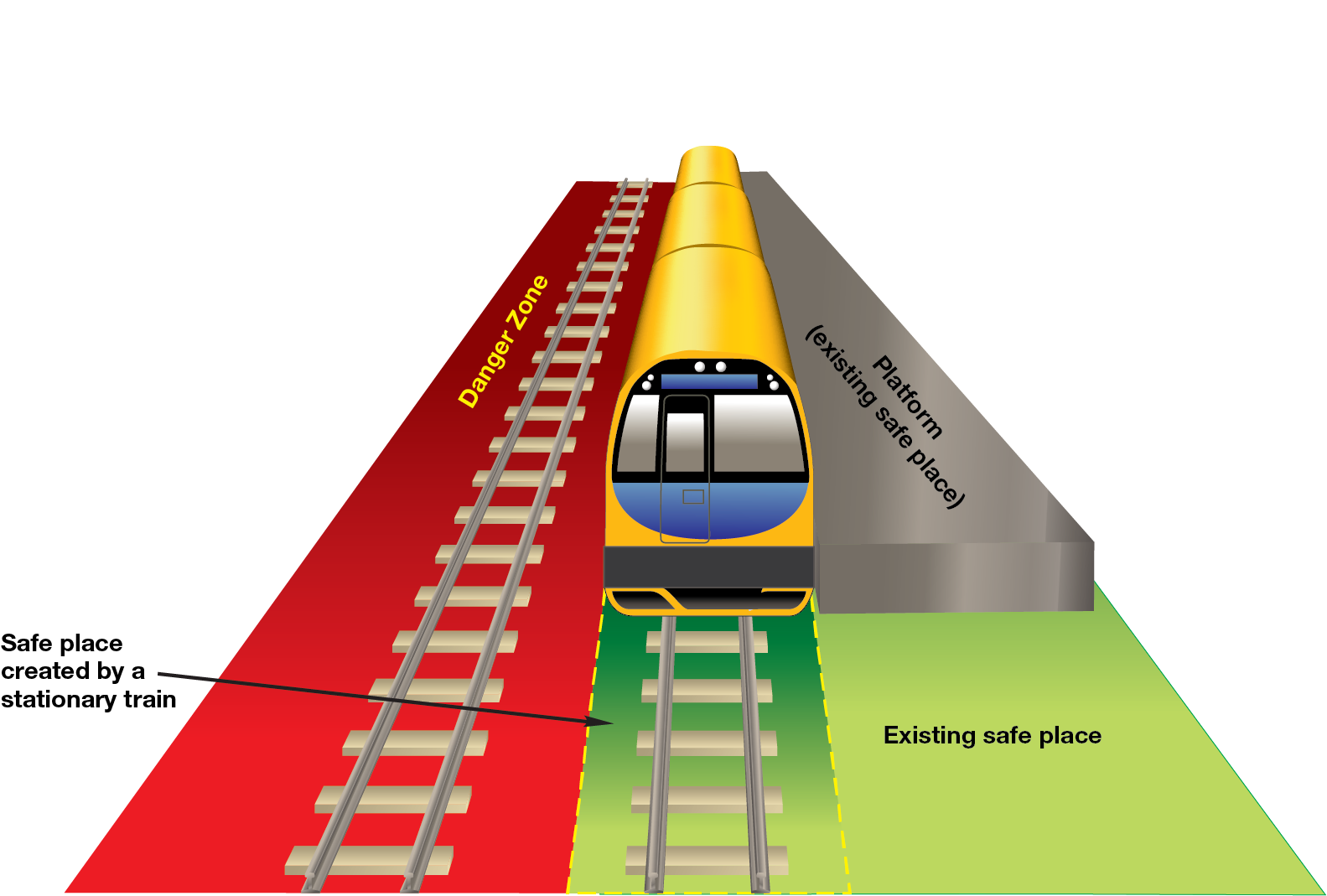

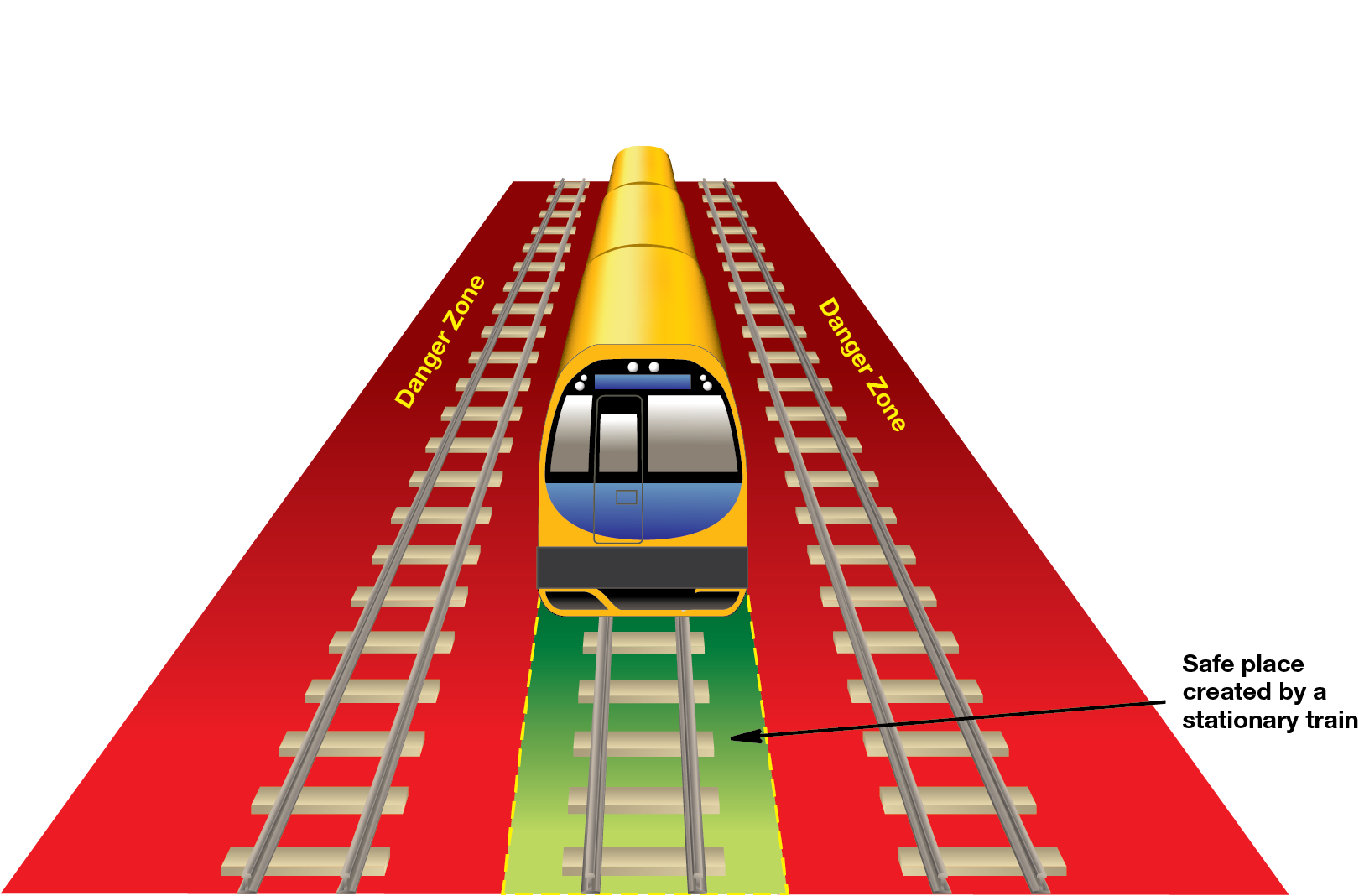

Activities associated with in-service rail traffic may be carried out:

- in an existing safe place, or

- in a safe place created using stationary rail traffic, or

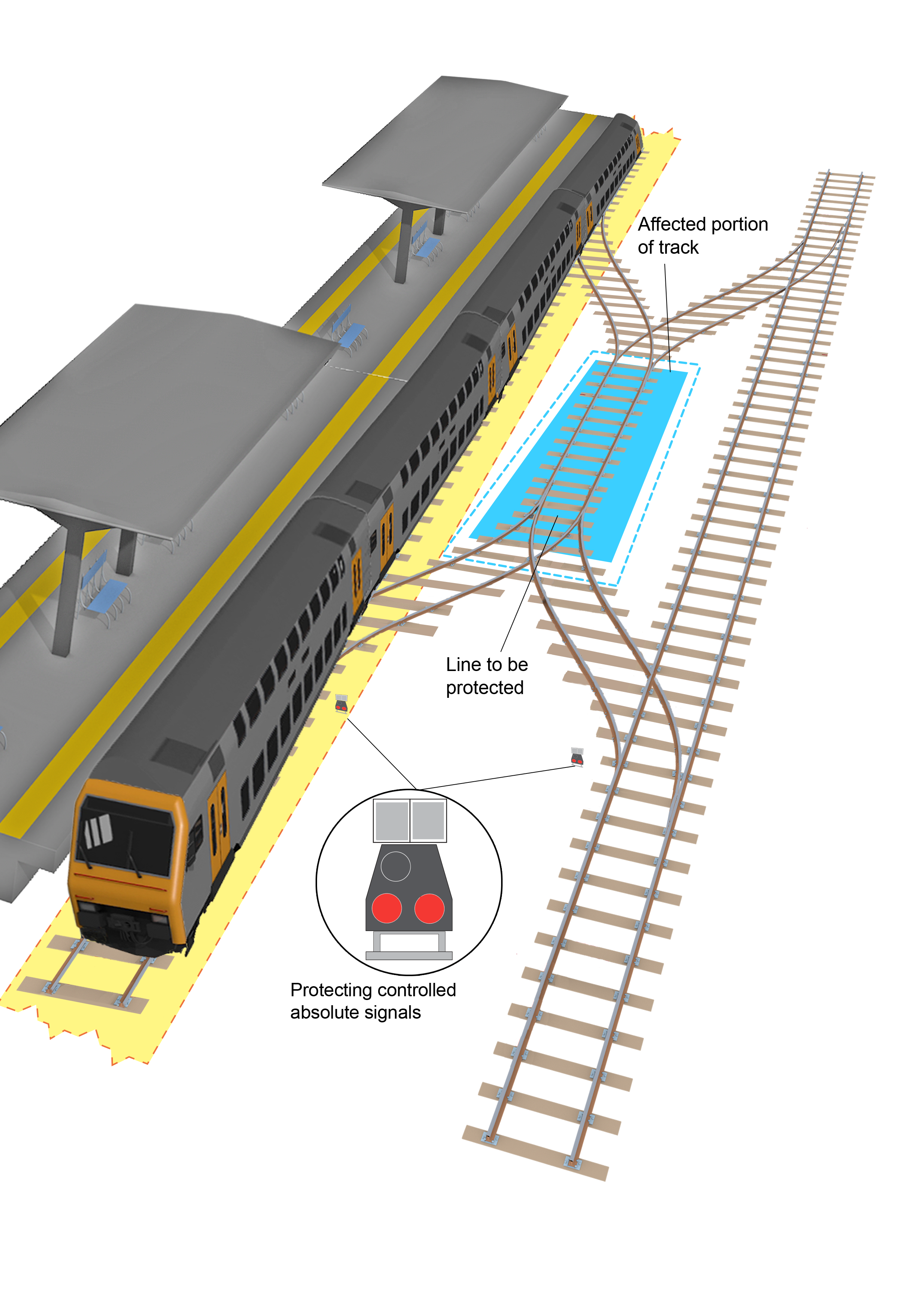

- on adjacent lines, if rail traffic has been excluded from the affected portions of track.

Requesting protection

Qualified Worker

- Tell the Signaller:

- your name, and

- your Safeworking designation, and

- the train number or track vehicle number, and

- the type of activity.

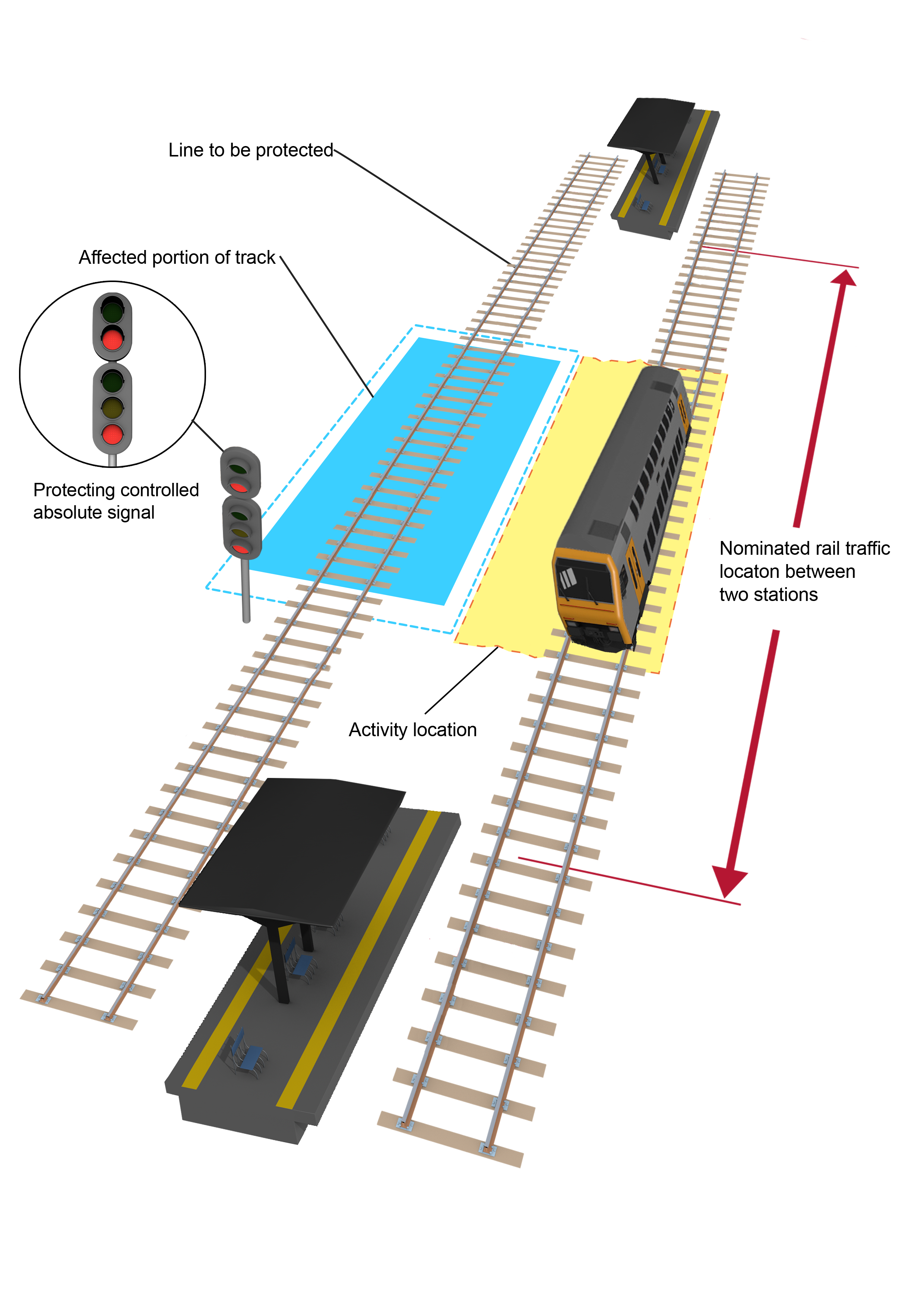

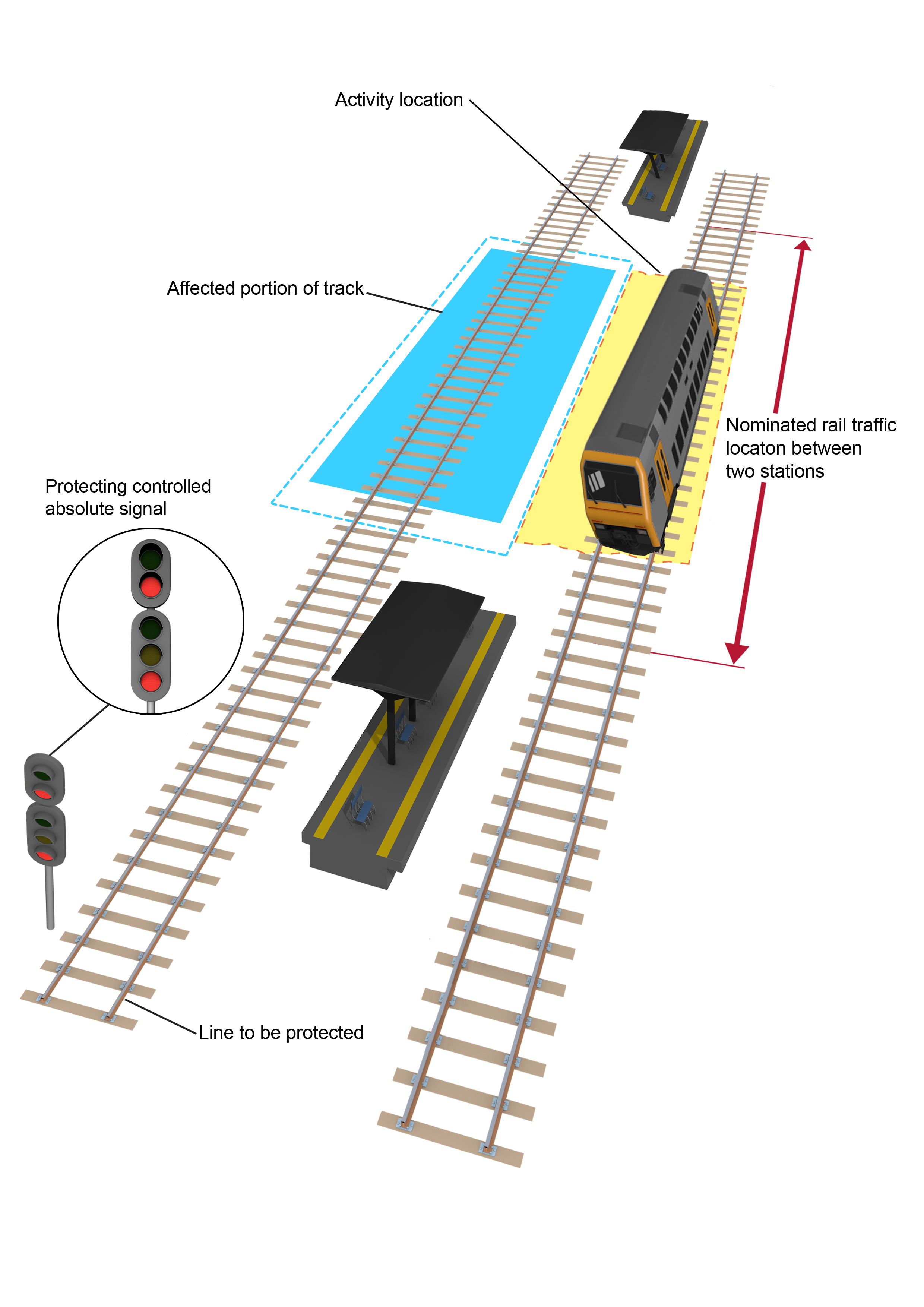

- Identify the line on which protection is required and nominate the rail traffic location as being:

- between any two stations, or

- completely within a nominated dead-end siding, or

- completely within the limits of a platform, including the station name and platform number.

Lines that need to be accessed must be protected when conducting activities associated with in-service rail traffic.

- Ask the Signaller to protect all routes allowing entry into the affected portion of track.

Signaller

- Confirm the protection request including:

- the Qualified Worker’s name, and

- the train number or track vehicle number, and

- the type of activity, and

- the line on which protection is required, and

- the nominated rail traffic location.

- Use the reference points provided by the Qualified Worker to identify the rail traffic location.

- Assess the rail traffic location to identify:

- the length of the rail traffic, and

- the affected portions of track to be protected, and

- all routes that allow entry to the affected portions of track.

Unless the affected portion of track is shorter than the rail traffic, the adjacent line must be protected for the full length of the rail traffic.

- Identify if the affected portions of track require more than one Signaller to exclude rail traffic. If the affected portions of track affect more than one Signaller, the Signallers must nominate an authorising Signaller.

Signaller/Authorising Signaller

- Make sure that:

- blocking facilities have been applied to exclude rail traffic, and

- the last rail traffic to enter the affected portions of track is identified and its location is known, and

- there is no approaching rail traffic between the protection and the affected portions of track.

Authorising Signaller

- Tell the Qualified Worker:

- that blocking facilities have been applied, and

- that the affected portions of track is protected, and

- the identification number of the last rail traffic to enter the affected portions of track and its last known location, and

- that there is no approaching rail traffic between the protection and the affected portions of track.

Qualified Worker

- Confirm with the Signaller:

- that all points of entry into the affected portions of track are correctly protected, and

- the identification number of the last rail traffic to enter the affected portions of track and its last known location, and

- that there is no approaching rail traffic between the protection and the affected portions of track

Authorising protection

Signaller

- After the Qualified Worker has confirmed the assurances:

- authorise the protection, and

- issue the protection number.

Qualified Worker

- Before entering the Danger Zone make sure that:

- the protection is authorised, and

- the protection number has been issued.

Conducting in-service inspections and repairs

Driver, Track Vehicle Operator or Train Technician

1. Before carrying out an in-service inspection or repair make sure that a safe place exists, or protection has been authorised.

Unless the worker conducting the inspection or repair requests a roll by inspection, rail traffic that is being inspected or repaired must not be moved until the activity is completed.

Train Technician

- If practicable:

- apply the parking brake, and

- open the brake pipe emergency tap, and

- place a red Train Technician safety sleeve (TT safety sleeve) over the brake pipe emergency tap.

If required, Qualified Workers must work as directed by the Train Technician.

Train Technician

- When work has been completed, tell the Driver or Track Vehicle Operator that work is complete, and if required:

- remove the TT safety sleeve, and

- close the brake pipe emergency tap, and

- release the parking brake.

Removing protection

Qualified Worker

- Tell the Signaller:

- the rail traffic location, and

- the train number or track vehicle number, and

- the protection number, and

- that workers and equipment are clear of the Danger Zone.

Signaller

- Before removing protection, confirm with the Driver, Track Vehicle Operator or Train Technician:

- the train number or track vehicle number, and

- the rail traffic location, and

- the protection number, and

- that workers and equipment are clear of the Danger Zone.

Keeping Records

Signallers and Qualified Workers must record the protection details in permanent form.