Description

This document describes the procedure for planning, implementing and managing a Track Work Authority (TWA).

Not what you are looking for? See more Procedures

Introduction

A Track Work Authority (TWA) allows track work on running lines between rail traffic movements. Protection Officers manage the approach of rail traffic to worksites. Rail traffic may pass through worksites only under controlled conditions.

Workers must be in safe places before rail traffic is allowed to pass the inner Handsignaller or pass through the limits of worksites.

Train Running Information provides only a guide to planned movements and cannot be relied upon.

Protecting worksites

The outer Handsignaller must be put in place before the inner Handsignaller.

Protection Officer

- Protect worksites by:

- managing the approach of rail traffic to worksites, and

- managing the transit of rail traffic through worksites, and

- if necessary, managing rail traffic on other lines.

- Make sure that all protection is correctly placed.

- Where practicable, reduce the number of routes allowing entry to a worksite area by clipping and locking points.

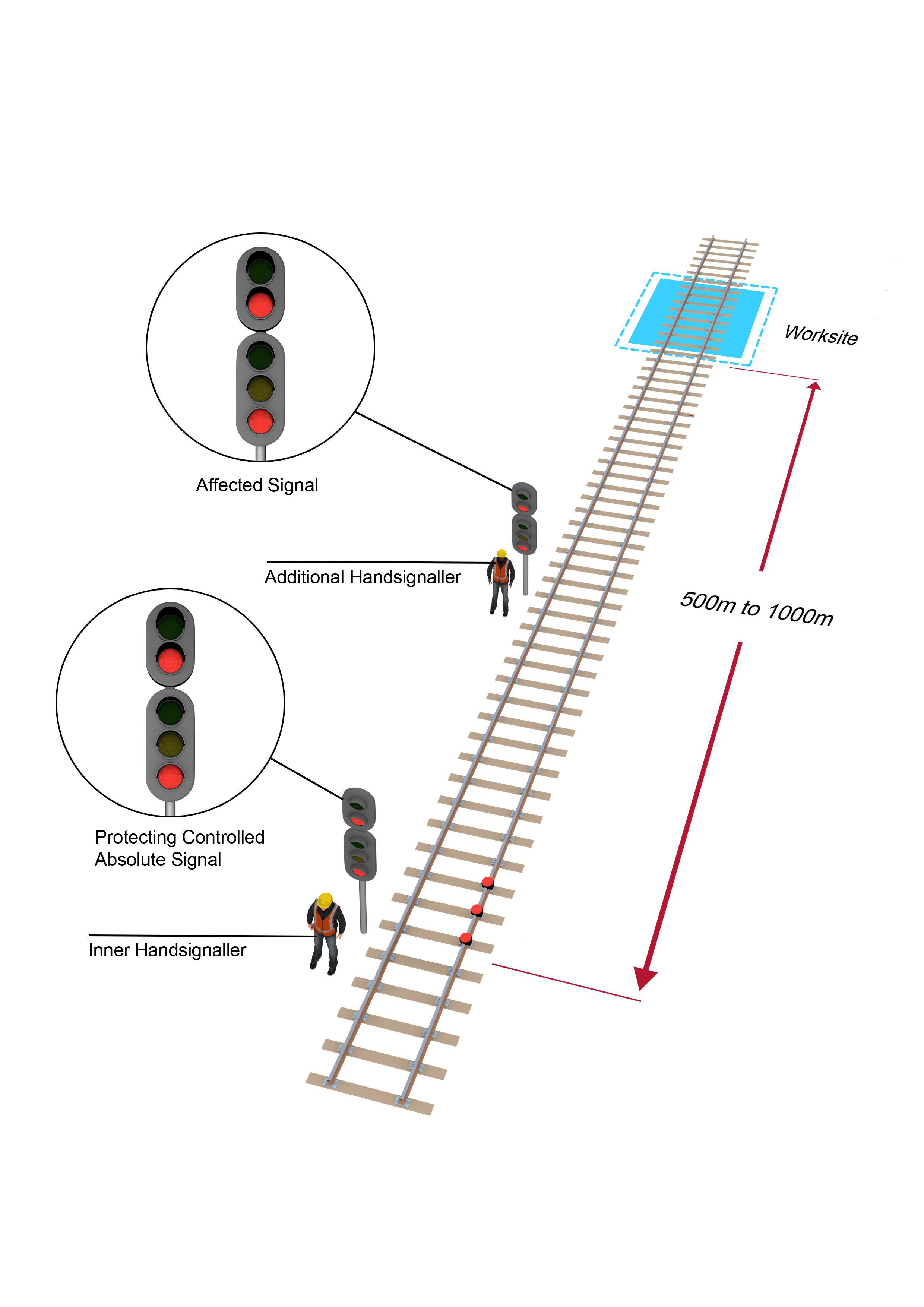

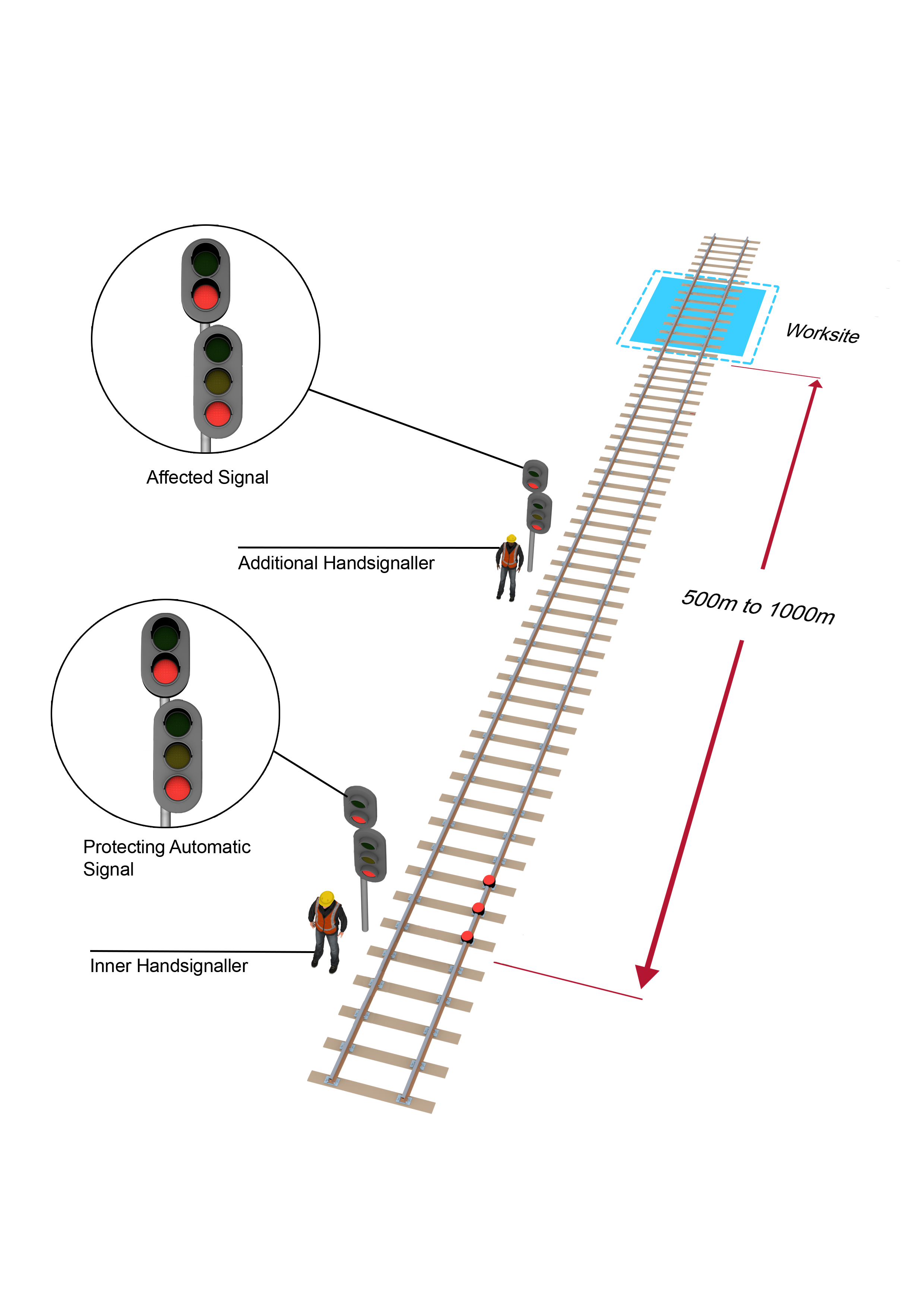

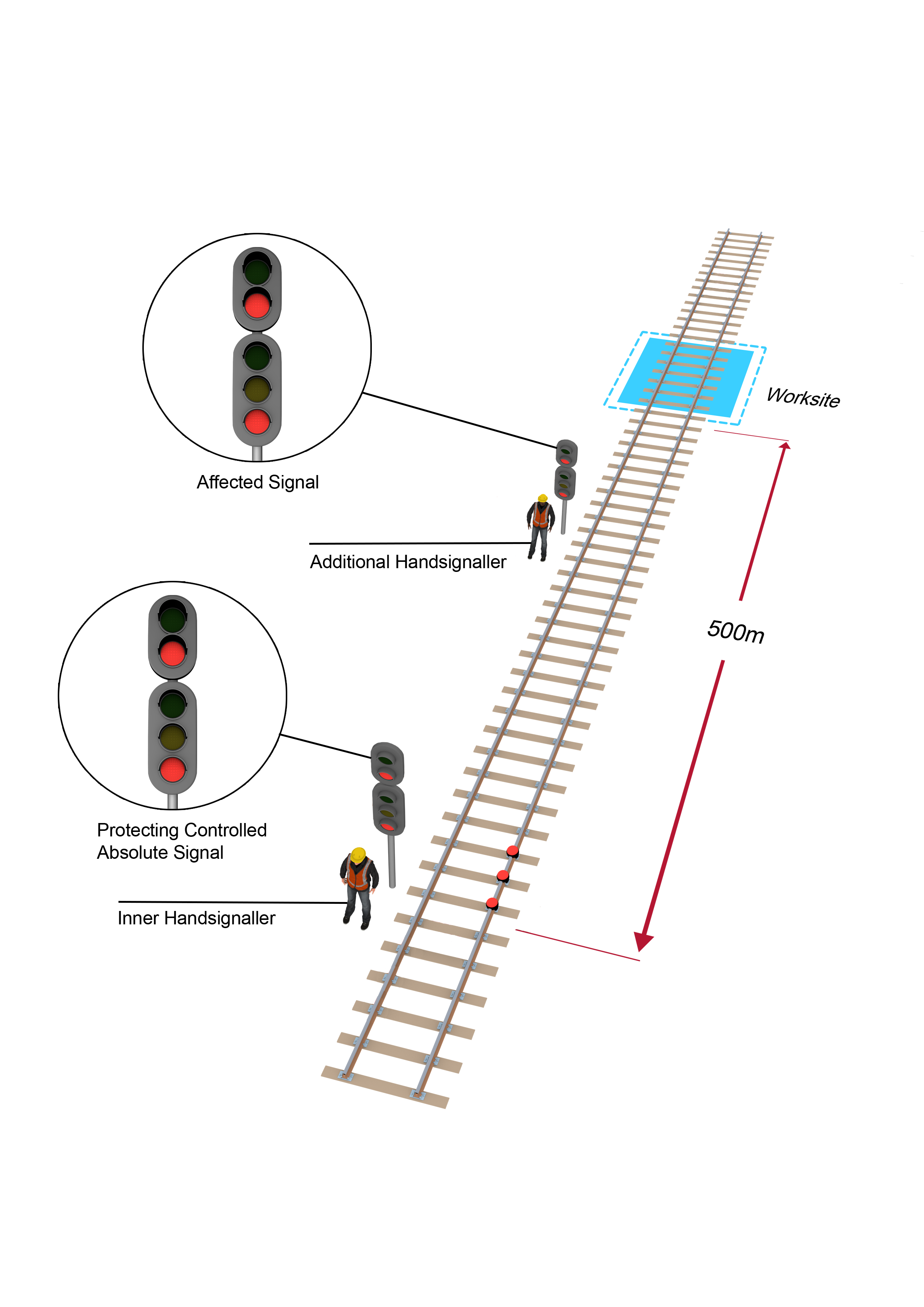

Managing signals affected by work on track

Work on track may affect signals so they display STOP. In this procedure these signals are called affected signals.

Protection Officer

- Arrange for affected signals to be set and held at STOP.

- Place a Handsignaller at each affected signal, in the direction of approaching rail traffic.

- Tell the Handsignaller to display a STOP handsignal to approaching rail traffic.

- If the affected signal is a controlled absolute signal, direct the Handsignaller to get the Signaller’s authority to allow the rail traffic to pass the signal at STOP.

- If the affected signal is an automatic signal, give the Handsignaller instructions about allowing rail traffic to pass the signal at STOP.

Handsignaller

- If the affected signal is a controlled absolute signal, follow the Protection Officer’s directions, and get the Signaller’s authority to allow the rail traffic to pass the signal at STOP.

- If the affected signal is an automatic signal, follow the Protection Officer’s instructions to allow rail traffic to pass the signal at STOP.

Managing rail traffic approaches to worksites

Protection Officer

- Decide if it is safe for rail traffic to transit the worksite.

- Decide the appropriate speed for rail traffic to transit the worksite.

- Tell the inner Handsignaller whether to handsignal Drivers or Track Vehicle Operators to:

- travel through the worksite at normal speed, or

- travel through the worksite at caution, or

- stop and be told about special travel conditions.

Protecting worksites using Handsignallers at protecting signals

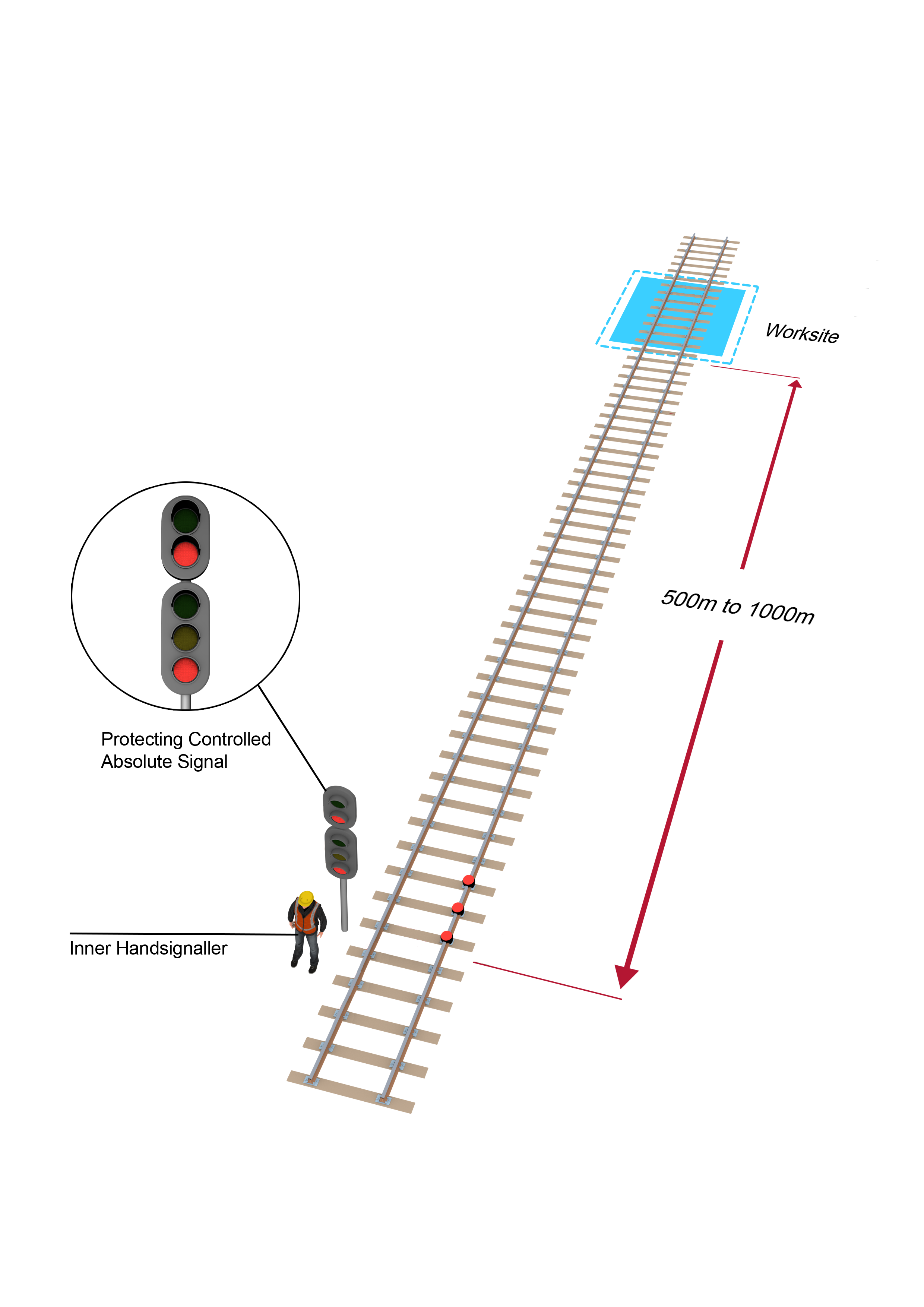

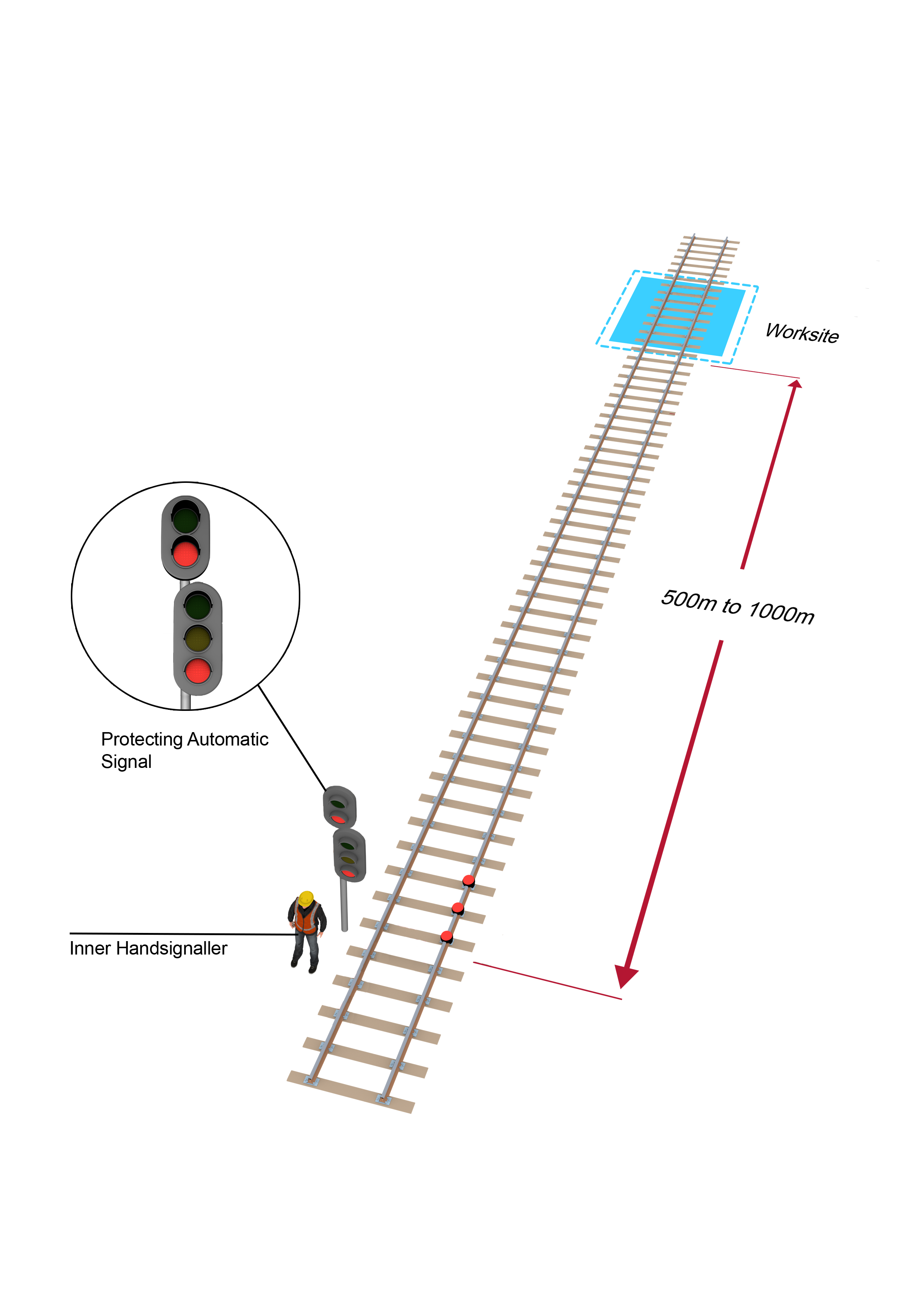

Signals between 500m and 1000m before the worksite

Protection Officer

- Arrange for the last signal in the direction of approaching rail traffic, between 500m and 1000m before the worksite, to be set and kept at STOP:

- at a controlled absolute signal by asking the Signaller, or

- at an automatic signal:

- by making arrangements with the authorised Maintenance Representative, or

- by operating a signal key switch, if fitted, in accordance with NPR 754 Using a signal key switch.

- Place an inner Handsignaller and three railway track signals at this last signal.

- If there are affected signals, place a Handsignaller at each affected signal.

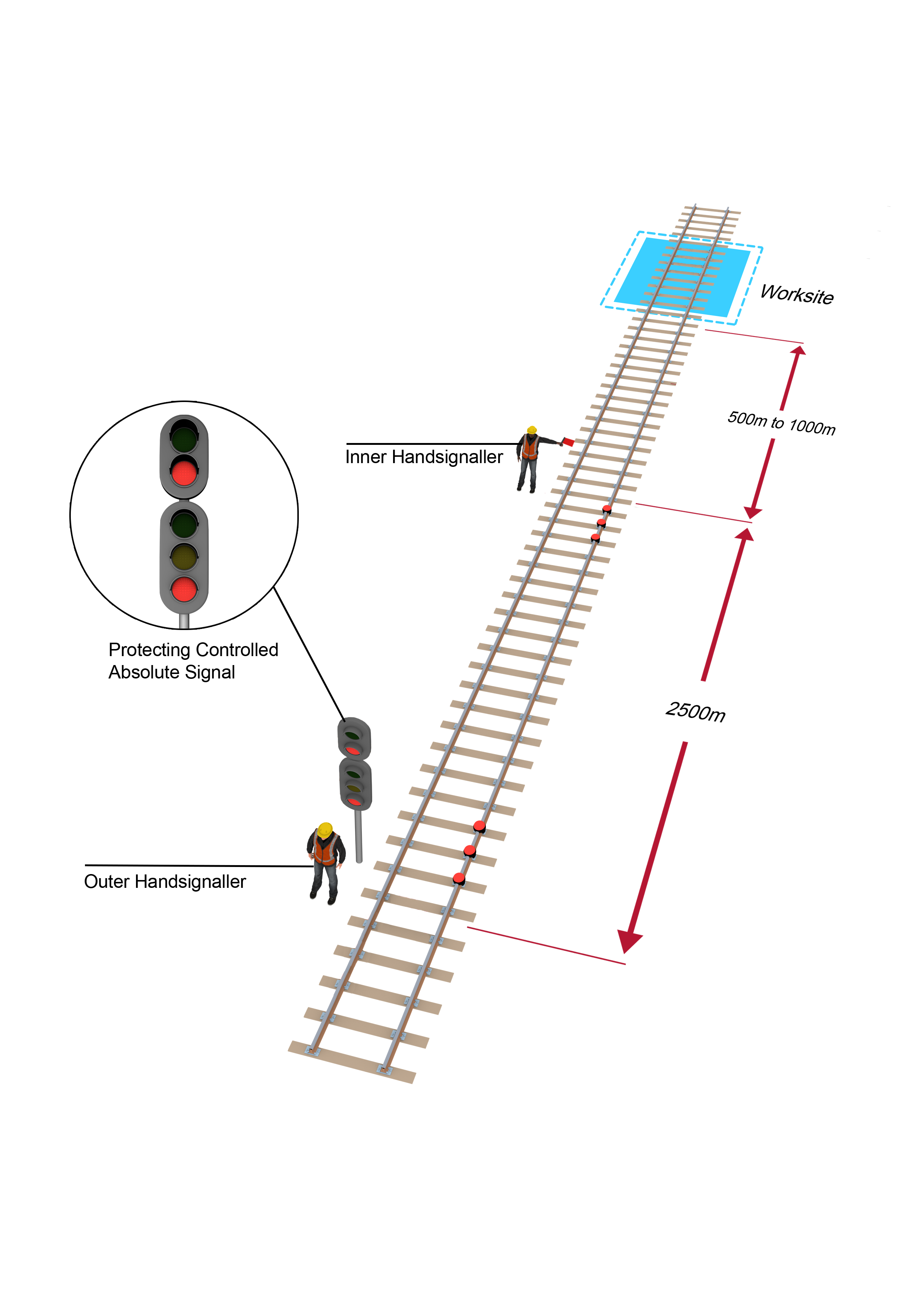

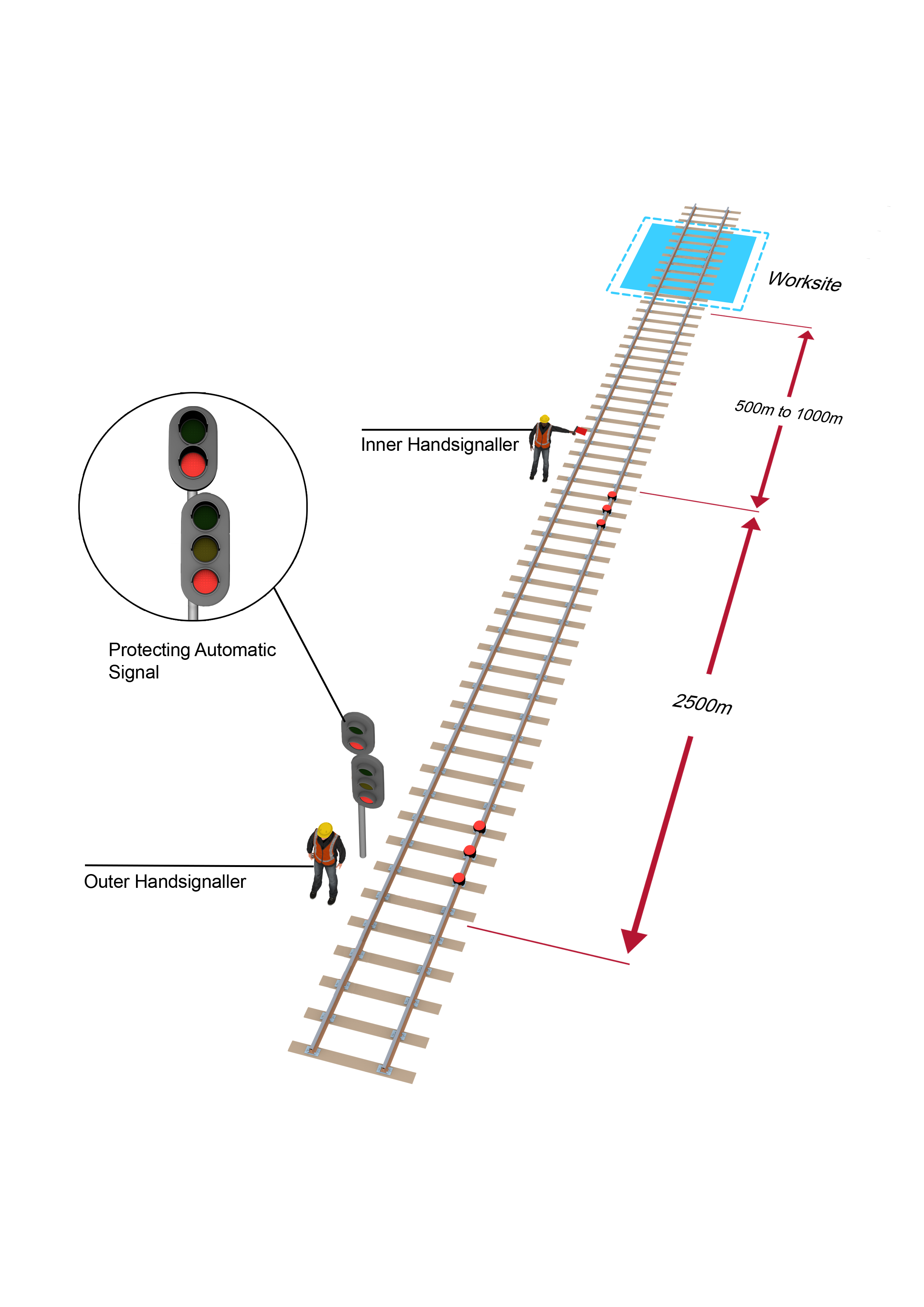

Signals more than 1000m and less than 3500m before the worksite

Protection Officer

- If there are no signals between 500m and 1000m before the worksite in the direction of approaching rail traffic, arrange for the last signal within 2500m of where the inner Handsignaller will be positioned to be set and kept at STOP:

- at a controlled absolute signal by asking the Signaller, or

- at an automatic signal:

- by making arrangements with the authorised Maintenance Representative, or

- by operating a signal key switch, if fitted, in accordance with NPR 754 Using a signal key switch.

- Place an outer Handsignaller and three railway track signals at this signal.

- Place the inner Handsignaller and three railway track signals between 500m and 1000m before the worksite.

- If the distance between the outer Handsignaller and the inner Handsignaller at the signal is less than 2500m, tell the outer Handsignaller to warn Drivers and Track Vehicle Operators about the reduced distance.

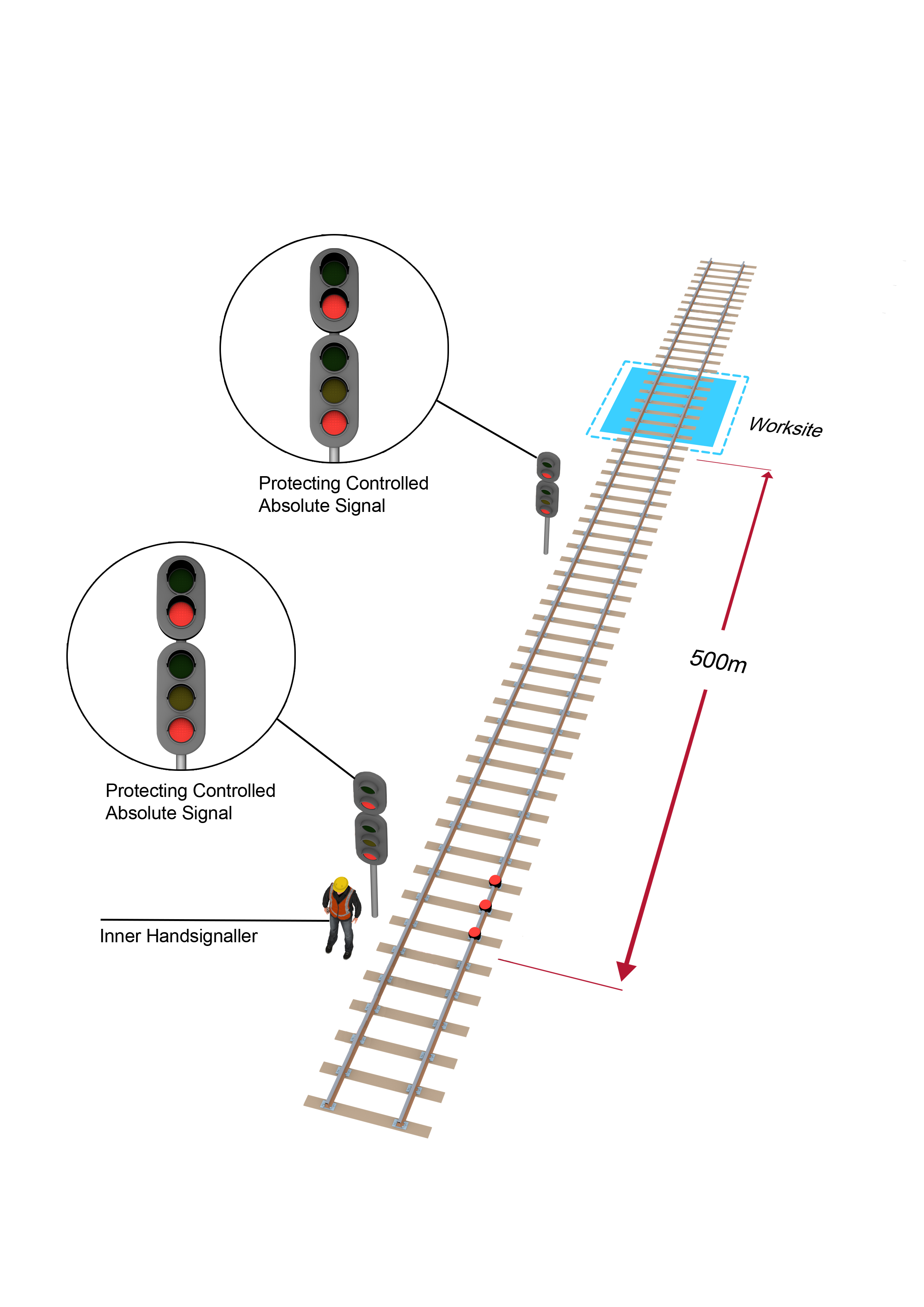

At least two controlled absolute signals within 500m of the worksite

Protection Officer

If there are at least two controlled absolute signals within 500m of the worksite.

- Ask the Signaller to set and keep both signals at STOP.

- Place the inner Handsignaller and three railway track signals at the first signal in the direction of approaching rail traffic.

- If the other signals can be cleared, further Handsignallers are not necessary.

- If there are affected signals, place a Handsignaller at each affected signal.

Protecting worksites using Handsignallers only

Protection Officer

- Choose locations where Handsignallers, Drivers and Track Vehicle Operators can see each other clearly.

- Place an outer Handsignaller and two railway track signals 2500m from where the inner Handsignaller will be positioned in the direction of approaching rail traffic.

- Tell the outer Handsignaller to display a CAUTION handsignal to approaching rail traffic.

- Place an inner Handsignaller and three railway track signals between 500m and 1000m before the worksite in the direction of approaching rail traffic.

- Tell the inner Handsignaller to display a STOP handsignal to approaching rail traffic.

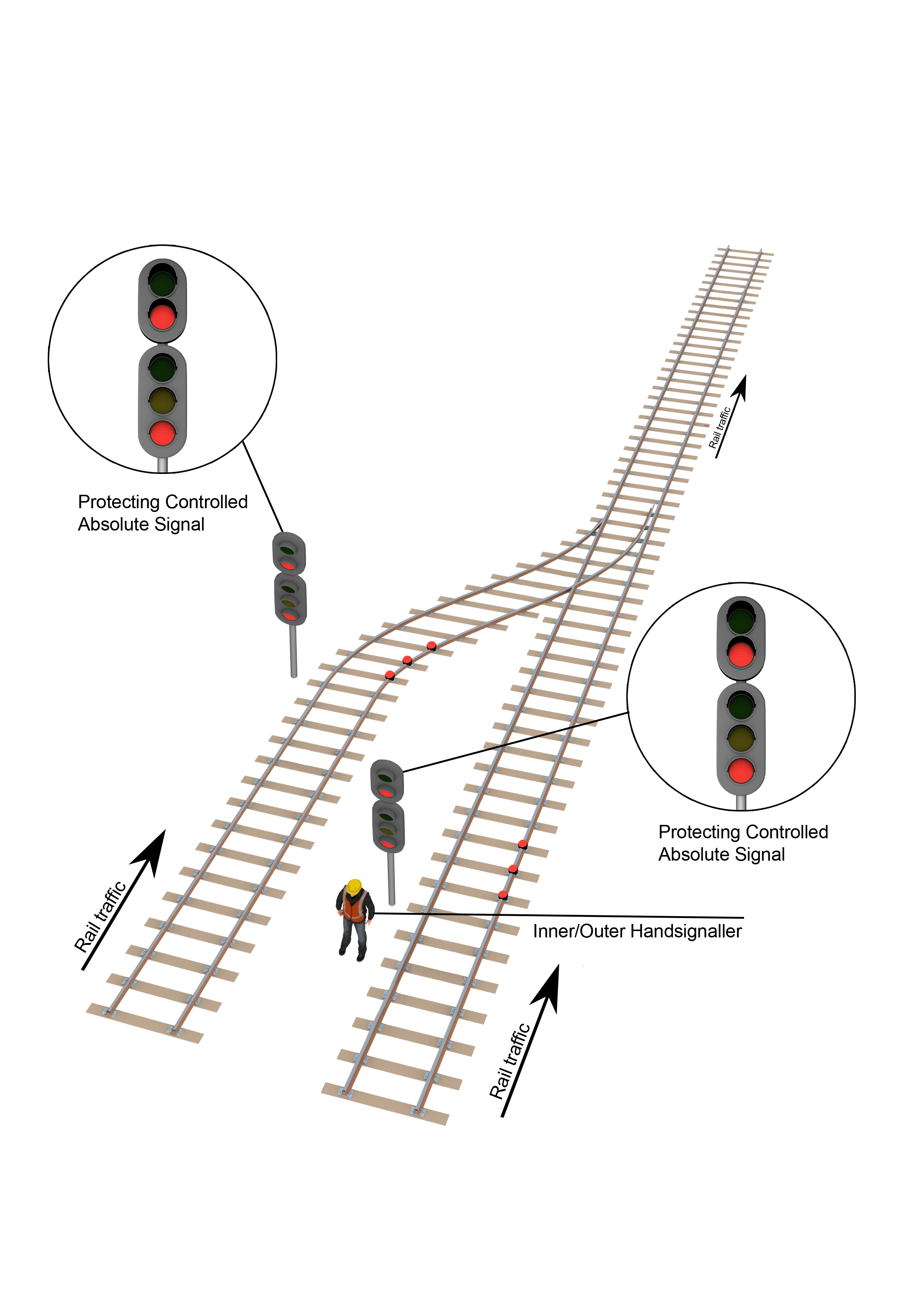

Placing protection for converging lines

Placing railway track signals at each signal

Protection Officer

- Place three railway track signals at each signal. Place the Handsignaller in a safe place, where approaching rail traffic on either line can be seen.

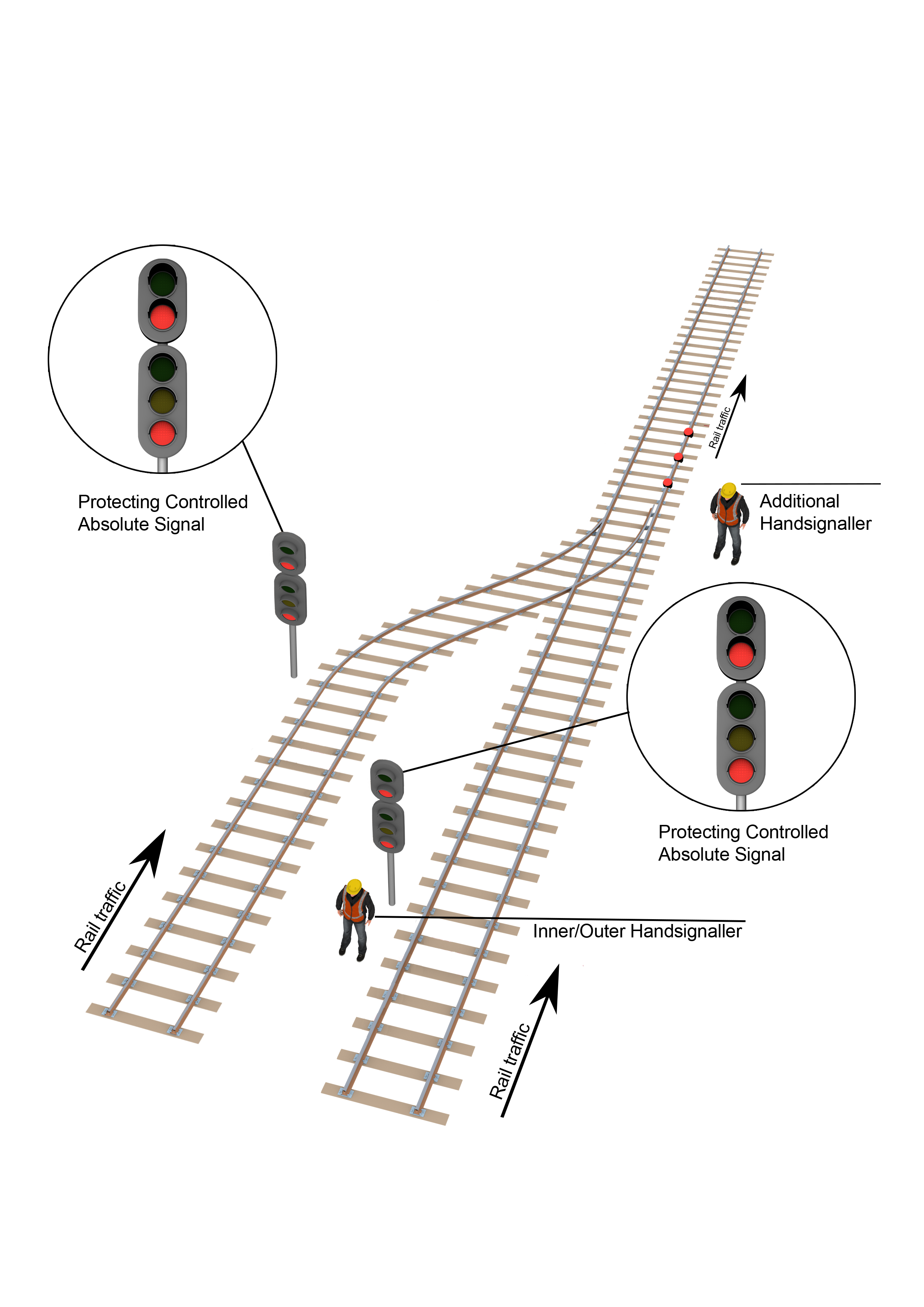

Placing railway track signals beyond crossovers

Protection Officer

- Place a Handsignaller in a safe place, where approaching rail traffic on either line can be seen.

- Place three railway track signals within 20m beyond the crossovers in the direction of travel.

- If it safe for rail traffic to pass the Handsignaller tell the Handsignaller the appropriate actions to follow.

- If necessary, place an additional Handsignaller responsible for placing and removing railway track signals and make sure that effective communication is maintained between the Handsignallers.

Handsignaller

- If necessary, ask the additional Handsignaller to remove and replace the railway track signals as instructed by the Protection Officer.

Additional Handsignaller

- If it is safe to do so, remove railway track signals when instructed by the Handsignaller.

- Replace railway track signals after each rail traffic movement.

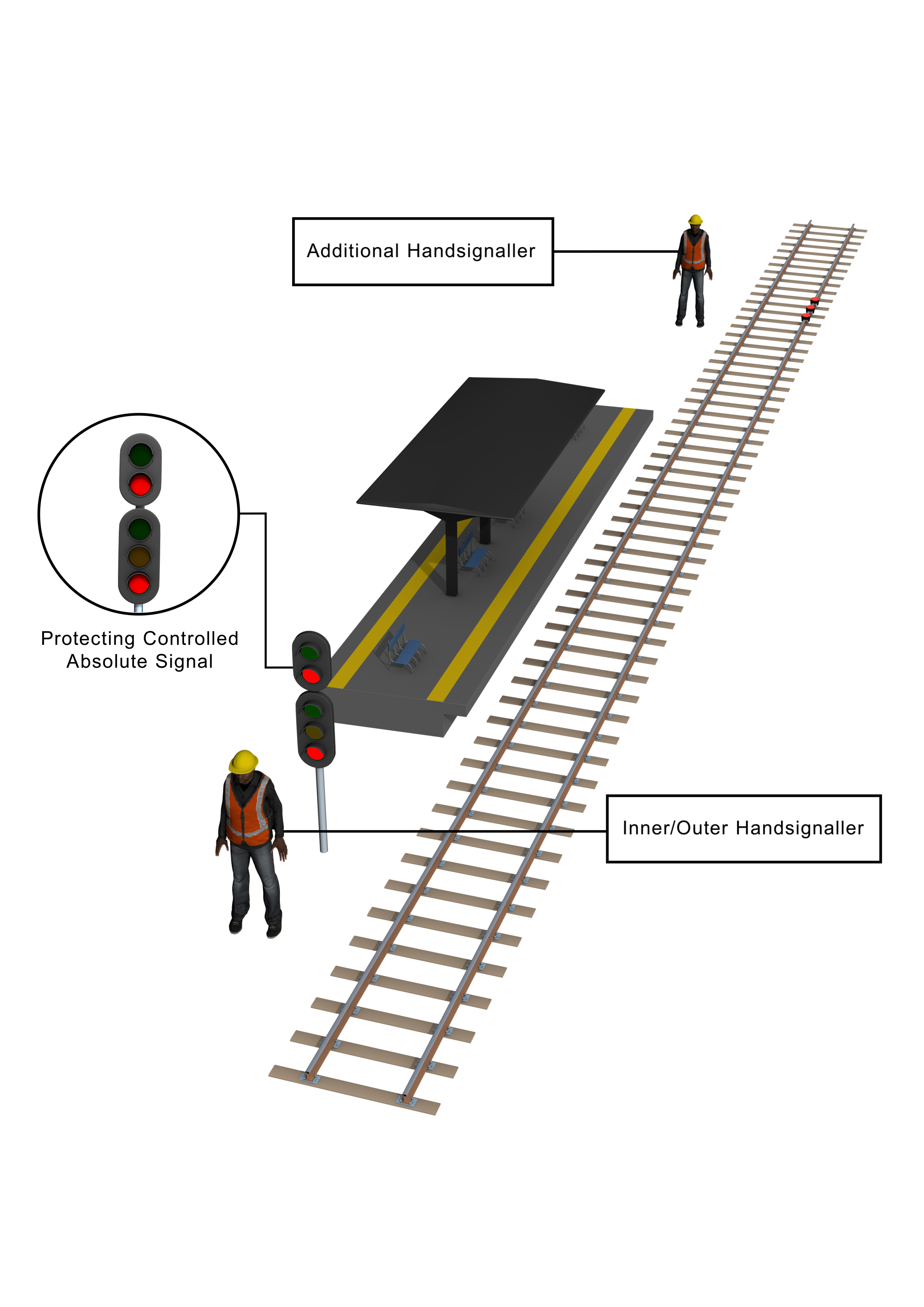

Placing protection near a platform

Protection Officer

- If a platform prevents railway track signals from being placed within 20m beyond the protecting signal, place a Handsignaller at the signal.

- Place three railway track signals beyond the platform in the direction of travel.

- If it safe for rail traffic to pass the Handsignaller tell the Handsignaller the appropriate actions to follow.

- Place an additional Handsignaller responsible for placing and removing railway track signals and make sure that effective communication is maintained between the Handsignallers.

Handsignaller

- If necessary, ask the additional Handsignaller to remove and replace the railway track signals as instructed by the Protection Officer.

Additional Handsignaller

- If it is safe to do so, remove railway track signals when instructed by the Handsignaller.

- Replace railway track signals after each rail traffic movement.

Managing rail traffic transits through worksites

Protection Officer

- Before authorising the inner Handsignaller to signal rail traffic to approach and pass through a worksite, make sure that:

- workers have gone to the designated safe places, and

- the line is clear of workers and equipment between the worksite and the inner Handsignaller’s location, and

- the line is clear and safe for the passage of rail traffic through the worksite, and

- if an automatic signal is being kept at STOP to protect a worksite, the line is clear to the first signal beyond the worksite.

- If it is safe for rail traffic to pass the outer Handsignaller at a controlled absolute signal, tell the Handsignaller to take the following actions:

| Movement allowed | outer Handsignaller action |

|---|---|

Rail traffic is to proceed at caution |

|

- If it is safe for rail traffic to pass the inner Handsignaller at a controlled absolute signal, and pass through the worksite, tell the Handsignaller to take the following actions:

| Movement allowed | inner Handsignaller action |

|---|---|

Rail traffic is to proceed at normal speed |

|

Rail traffic is to proceed at caution |

|

Rail traffic is to proceed under special conditions |

|

- If it is safe for rail traffic to pass the outer Handsignaller at an automatic signal, tell the Handsignaller to take the following actions:

| Movement allowed | outer Handsignaller action |

|---|---|

Rail traffic is to proceed at caution |

|

- If it is safe for rail traffic to pass the inner Handsignaller at an automatic signal, and pass through the worksite, tell the Handsignaller to take the following actions:

| Movement allowed | inner Handsignaller action |

|---|---|

Rail traffic is to proceed at caution |

|

Rail traffic is to proceed under special conditions |

|

- If it is safe for rail traffic to pass the outer Handsignaller at an automatic signal fitted with a signal key switch, tell the Handsignaller to take the following actions:

| Movement allowed | outer Handsignaller action |

|---|---|

Rail traffic is to proceed at caution |

|

- When rail traffic has cleared the worksite, confirm with the Handsignaller:

- that the key was removed immediately after the leading vehicle completely passed the signal, and

- that the signal is displaying a STOP indication.

- If it is safe for rail traffic to pass the inner Handsignaller at an automatic signal fitted with a signal key switch, tell the Handsignaller to take the following actions:

| Movement allowed | inner Handsignaller action |

|---|---|

Rail traffic is to proceed at normal speed |

|

Rail traffic is to proceed at caution |

|

Rail traffic is to proceed under special conditions |

|

- When rail traffic has cleared the worksite, confirm with the Handsignaller

- that the key was removed immediately after the leading vehicle completely passed the signal, and

- that the signal is displaying a STOP indication.

- If it is safe for rail traffic to pass the outer Handsignaller not at a signal, tell the Handsignaller to take the following actions:

| Movement allowed | outer Handsignaller action |

|---|---|

Rail traffic is to proceed at caution |

|

- If it is safe for rail traffic to pass the inner Handsignaller not at a signal, and pass through the worksite, tell the Handsignaller to take the following actions:

| Movement allowed | inner Handsignaller action |

|---|---|

Rail traffic is to proceed at normal speed |

|

Rail traffic is to proceed at caution |

|

Rail traffic is to proceed under special conditions |

|

If there is not enough time to remove the railway track signals safely, leave them on the track and signal STOP to the approaching rail traffic.

- Make sure the inner and outer Handsignallers have replaced the railway track signals immediately after each rail traffic movement has passed.

Rail traffic clearing multiple worksites

Protection Officer

- Place a CLEARANCE sign or Handsignaller at least 50m beyond the last worksite.

Drivers and Track Vehicle Operators

- Resume normal speed only after the rear of the last vehicle has passed the CLEARANCE sign or the Handsignaller.

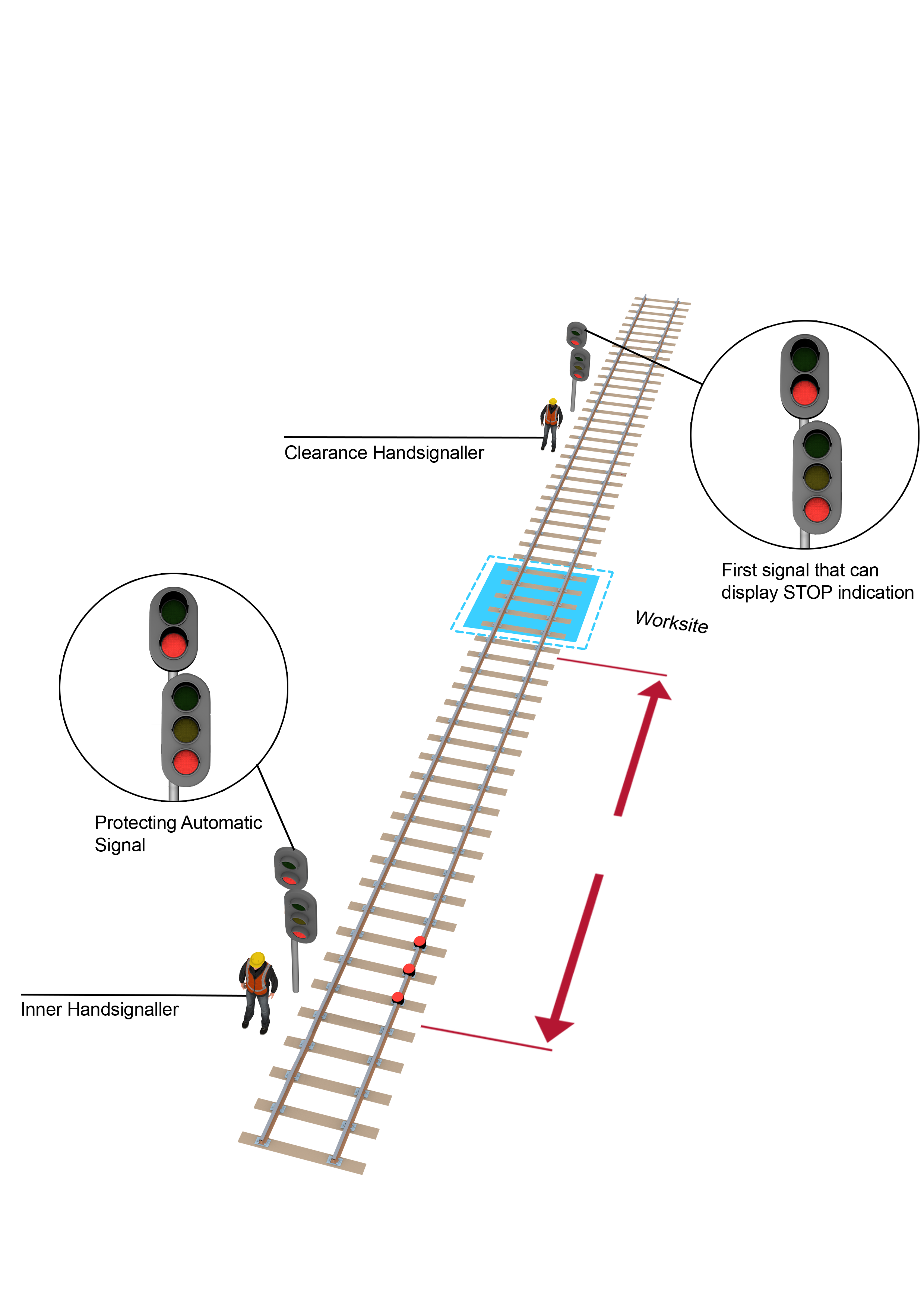

Using clearance Handsignallers if protecting signals cannot be cleared

Protection Officer

- Place a clearance Handsignaller at the first signal beyond the worksite that can display a STOP indication.

Clearance Handsignaller

- Make sure that the line is clear for rail traffic to approach.

- Tell the Protection Officer when rail traffic has passed complete beyond the signal and that the line is clear.

Using clearance Handsignallers if tonnage signals are affected

Protection Officer

- If a tonnage signal is affected by work on track or is being used to control rail traffic approaching the worksite, a clearance Handsignaller must be placed at the signal controlling the tonnage signal.

Clearance Handsignaller

- Tell the Protection Officer when the line is clear for rail traffic as far as that signal.

Returning the track to service

Protection Officer

- Make sure that all equipment is clear of the Danger Zone.

- Make sure that all workers have cleared the worksites.

- Make sure that:

- protection has been removed, and

- if necessary, signals have been restored to normal use, and

- the track is safe for use.

- If removed, the signal key switch key is restored.

- Tell the Signaller that the work is complete, and about any restrictions on track use.

- Fulfil the TWA.

Signaller

- Confirm with the Protection Officer:

- their name, and

- the worksite limits, and

- that workers and equipment are clear of the Danger Zone, and

- that, if used, the signal key switch key has been restored, and

- that the work is complete, and about any restrictions on track use, and

- that the TWA is fulfilled.

- If applied, remove blocking facilities.

- Tell the Network Controller that the TWA is fulfilled, and about any restrictions on track use.

Keeping records

Network Controllers, Signallers and the Protection Officer must record, in permanent form, the TWA details, including protection arrangements.